People often get confused between a solar cell and a solar panel or solar module. To understand this difference we must first understand the solar chain in brief. Basically, the solar module is a final product. It consists of various components apart from the active solar portion, such as glass, frame, encapsulant, junction box, back sheet, etc. The first step for making the active solar portion is the crystalline ingot. This ingot is of 2 types depending on the choice of solar panel to be made. For

For example, in case of a monocrystalline solar panel, the ingot is a mono-crystalline silicon drawn usually by Siemens technology.

In case of a polycrystalline solar panel the ingot is polycrystalline silicon which is a randong silicon crystalline formation. After the initial step the silicon ingot is then sliced and cut into wafers. These wafers are typically of thickness of around 150 to 300 microns. The wafers are then converted into a solar cell by a number of chemical processes and steps such as PECVD and various coatings and layers are deposited on the wafer. Further a number of conducting paths are created in the form of a grid known as busbars and fingers. The purpose of the busbars and fingers is to carry the DC power generated by the active areas.

As explained above, the solar cells are of 2 types = monocrystalline and multicrystalline. They are available in different sizes and thicknesses. They are usually of a square or pseudo-square shape. Further, the common size of the solar cells is 125mm or 156mm. However, some 200 mm cells are also being made in a very limited quantity. These cells are made in different thicknesses ranging from 150micron to 300 microns.

Given below are a few images for a better understanding;-

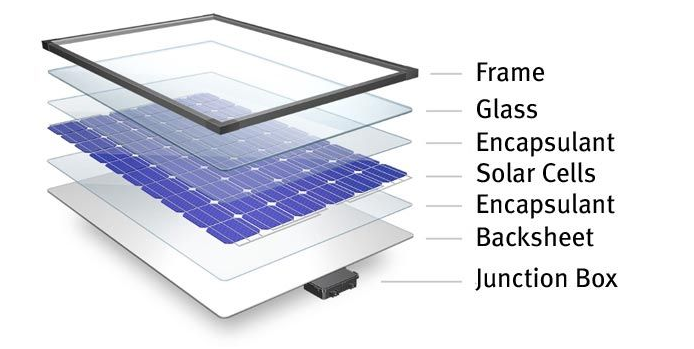

The solar cell is not usable by a consumer in this form because it is too delicate, sensitive and impossible to use in an actual solar system. It needs to be converted to a usable form. This form is called as a solar panel or also commonly referred to as a solar panel. A panel also referred to as a module, consists of multiple layers. The layers are shown in the image below :-

The topmost layer facing the sun is a solar toughened glass specially made for solar module manufacturing.

Then comes the layer of a grid of solar cells which have been interconnected together to allow the DC power to flow to the junction box. Then comes another layer of the encapsulant. Finally at the back is a layer of the back sheet to protect the other layers from moisture, dust, other environmental factors. And to draw all the solar power is a junction box with 2 cable leads. Further, this whole construction is protected by an anodized aluminum frame to provide the required rigidity and strength and enable it to be mounted on various kinds of structures. The above raw materials and a number of other minor raw materials together are then processed and finally made into a solar panel.

This solar panel (image below) is basically a product that can be used in a variety of solar systems to be able to reap the benefits of solar energy!